|

Sample Name: Great Wall Automobile hood prototype

|

|

Material: ABS

|

|

Processing technology: CNC machining

|

|

Color: Natural color

|

|

Surface treatment: sanding, bonding assembly

|

|

Accuracy: 0.02MM

|

|

Applications: Auto parts

|

|

Sample type: function prototype

|

|

Period: 3 days

|

User requirements: According to the provided 3D model data and specific production requirements, strictly control the quality to ensure that the production parts are matched with the real car.

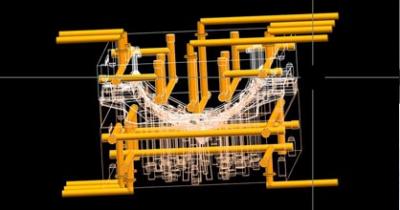

Project Analysis:

After receiving the drawings from the customer, our professional pre-analysts first check the 3D drawings and make the necessary disassembly, determine the assembly structure, and then select the appropriate materials and production processes. For this kind of functional automobile parts, the prototype parts are usually finished by CNC machining with ABS material. Because the viscosity of ABS material is better, the effect on strength is not significant when parts are split.

Processing

1. CNC machining

The tool on the

CNC machining center moves on the material according to the path set by the program, and removes the excess part of the material to obtain the prototype of the hand model.

CNC machining

2. Hand polished

The CNC-machined hood prototype has a rough surface and a lot of burrs and knives. It needs to be sanded away to make it look smoother. It should be sanded with coarse sandpaper and then with fine sandpaper.

Finely sanded, sanded from coarse to fine sandpaper (400-1500) level grinding until the surface is smooth

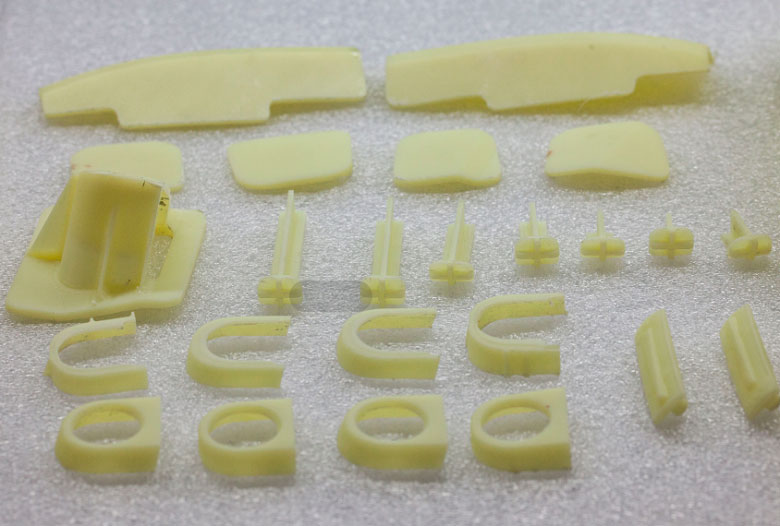

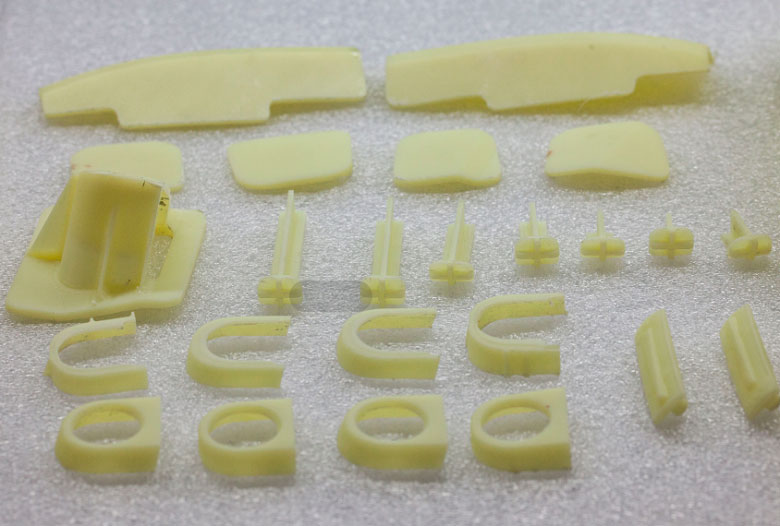

3. Hand bonding

Hand-bonded assembly is the most critical step in the making of this part, and it is extremely demanding on the level of operation of our technical team. Due to the large number of parts to be split, after the CNC is completed, we need to glue the parts together by hand bonding. In the bonding process, we need skilled technicians to carefully bond the small parts, and continue to test until the bond is tight and firm, and try to make the gap required by the customer as small as possible to achieve the best match!

Split Parts

Prototype skilled worker carefully looks through the 3D drawings and preliminarily tests high matching degree of the whole model by hand-made rough binding

Perfect assembly: Careful gluing of all components for perfection

Finished product

Duch Group has a world-class car model making team, rich experience in

prototype production, and is equipped with more than 130 advanced CNC machines, complete technology and fast delivery. We are able to provide perfect model samples in just 3-5 days, which allows you to comprehensively and correctly evaluate new products before opening the mold, making product development smoother and greatly reducing product errors and risks. It is also convenient for customers to confirm, as well as for the early stage of the events such as exhibitions and advertisements. If you have a project similar to the one described in this article, please feel free to contact us!

+86-18659338188

+86-18659338188  [email protected]

[email protected]

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.