Advantages of Mass Production

With more than 500 high-speed, high-precision CNC machining equipment and world-class injection molding equipment, 20+ years of mold manufacturing experience, we can provide you with all-round services such as rapid mold manufacturing and injection molding mass production to achieve optimal production efficiency and effectively reduce production costs, providing a full range of rapid mass production solutions.

Mass Production Process

Mask: making mold, injection molding mass production

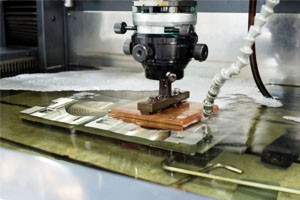

After solving the difficulties in making molds, we started to make molds. The mold core material is made of S136+ heat treatment, the hardness can reach 48-52 degrees, we use 50C for the mold base, through milling machine/deep hole drilling, CNC roughing, Heat treatment, grinding machine, CNC light knife, wire cutting, electric spark, polishing, fitter mold assembly process to make the mold efficiently, finally do the injection.

We offer professional mass scale production. We can also provide a variety of post-treatment methods, such as painting, screen printing, water transfer printing, polishing, sandblasting, electroplating, vacuum plating and so on. If you are looking for reliable mass production companies, please contact our professional team at

[email protected] or contact us by visiting our website, we will provide quotes and suggestions free of charge.

Student Graduation Design Case Study of Expressway Inspection & Emergency Treatment Engineering Vehicles

Student Graduation Design Case Study of Expressway Inspection & Emergency Treatment Engineering Vehicles

+86-18659338188

+86-18659338188  [email protected]

[email protected]

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.