Super, super light, durable, graphene magic is often hailed as the future of the material. The heat conduction and electrical conduction has high efficiency, has great potential in the field of electronic manufacturing, such as OLED, batteries, transistors and the photosensitive element, graphene will be applied in many fields.

As you can imagine, in combination with 3D printing, this is a bit like the Holy Grail of manufacturing. Last year, a research group in South Korea, the first successful use of 3D printing graphene nanowires.

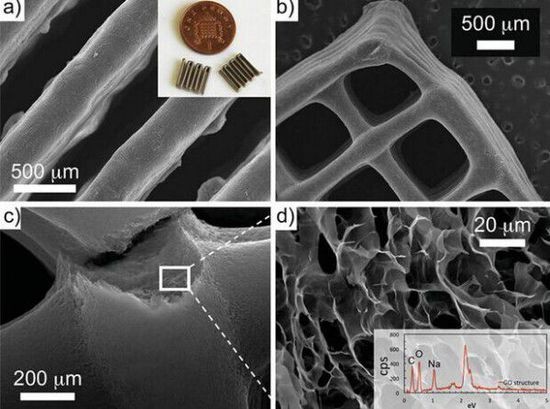

Now, a team from Imperial College in London, the 3D geometric structure of graphene complex out with 3D printing materials printing.

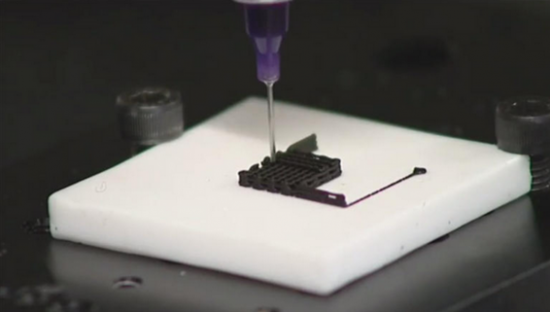

"We need the formulation of liquidity and physical properties of precipitation 3D printing technology required for filament, they need through the nozzle is very small, keep after sprayed and immediately solidified shape." Imperial College London, Dr. Esther Garcia Tunon said.

"We used a two-dimensional material as the basis, to create three-dimensional structure of macro, this technique is called direct ink, also called direct write assembly, or Robocasting."

The first is to print the structure of graphene, not for synthetic materials, 3D printing materials originally envisaged is added in a small amount of water-based ink. One problem is that graphene has strong hydrophobicity. The team used graphene oxide developed 3D printing ink, a treatment can be carried out in water in the form of chemically modified graphene.

This is a "smart" polymer, as long as the trigger it will change the shape and its performance. Such as temperature and some chemical substances. This ink can print 3D nanowires.

"The ink through the nozzle of 100 nm, the rheology of the ink can be customized according to the processing technology, such as extrusion type, gel type etc.." Dr. Garcia Tunon said.

"Now 3D print everywhere, we can find a lot of the sale of 3D printers, can print their own Hello Kitty protective sleeve iPhone. With a variety of materials for 3D printing device is still a long way." She said.

+86-18659338188

+86-18659338188  [email protected]

[email protected]

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.