Types of CNC Machining

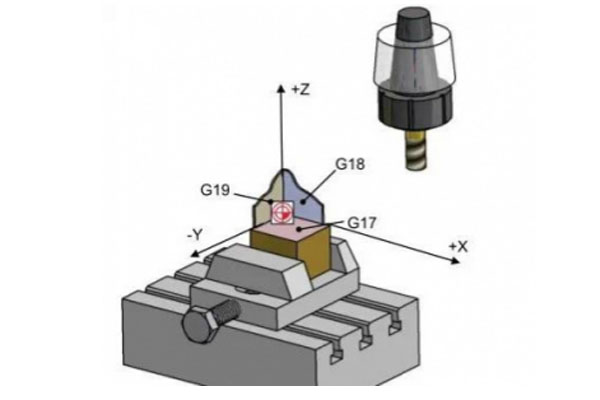

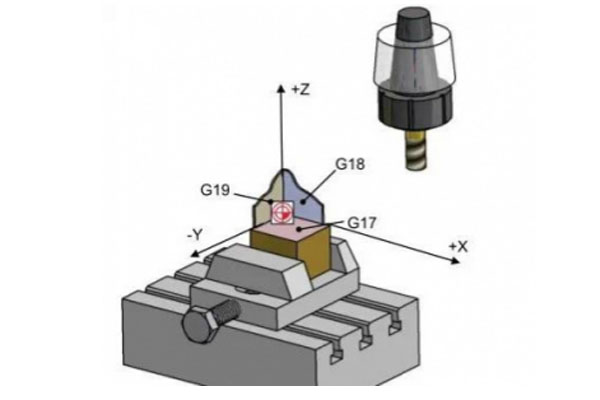

Three-axis CNC machining

The 3-axis machining is performed by straight lines to the axes X, Y, and Z.

Machining features: the cutting tool orientation remains constant during movement along the entire cutting path.

The 3-axis machining center has the advantages of high precision and high efficiency. It is commonly used to machine general parts, but it is more troublesome when machining complex workpieces, which may cause the workpiece to fail. Therefore, multi-axis simultaneous machining is the first choice when machining more complex workpieces.

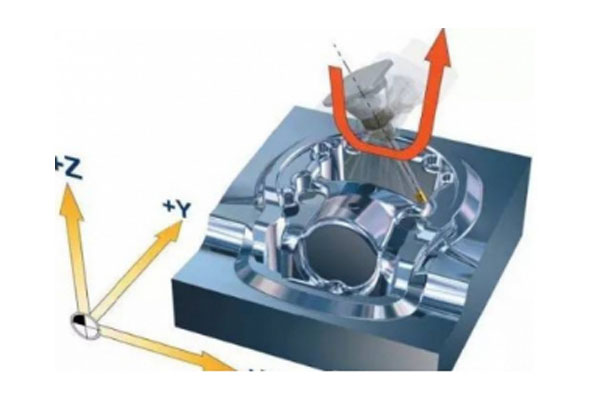

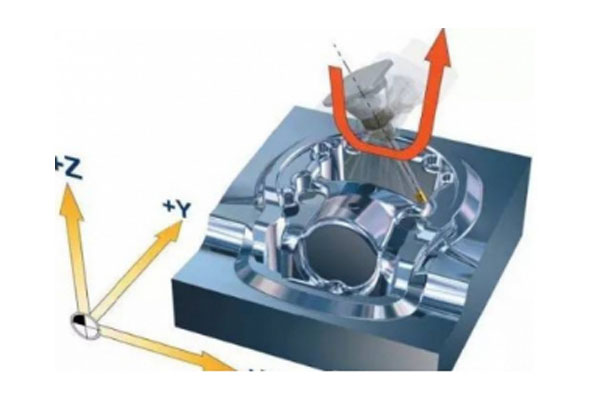

Five-axis CNC machining

Five-axis machining is the use of CNC to move parts or cutting tools on five different axes simultaneously, which can process very complex parts.

The remarkable feature of the five-axis linkage CNC machine tool is that it can complete the surface machining, and no special fixture is needed during machining, which greatly reduces the number of clamping and improves the machining accuracy, quality and efficiency. The five-axis machining center has unparalleled advantages in the processing of complex workpieces.

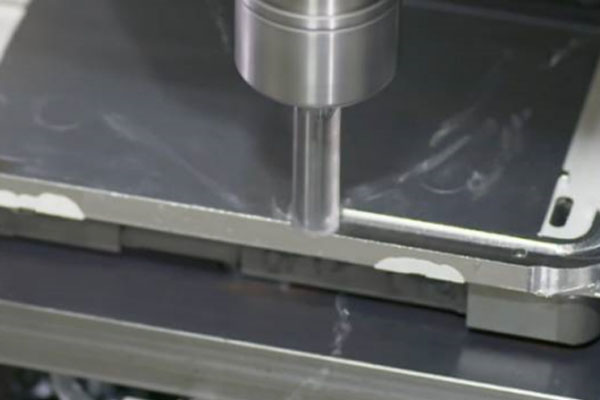

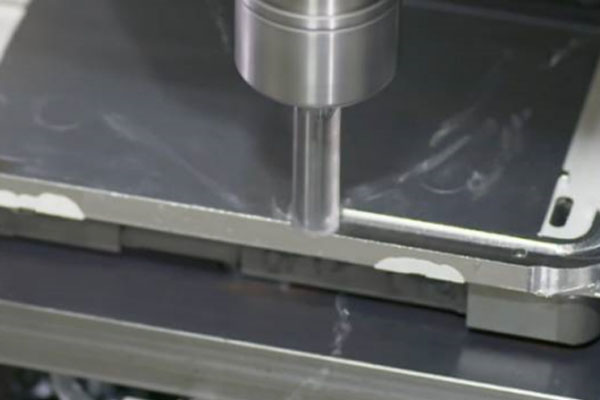

CNC milling

CNC milling machine processing is based on the technical requirements of the shape, accuracy, size and surface roughness of the workpiece to determine the processing technology and processing parameters. Program the machining program into the controller and send the command to the servo. CNC milling machines can process parts with particularly complex contours or difficult to control dimensions, such as mold parts and housing parts. It has the advantages of strong adaptability, high processing precision, stable processing quality and high efficiency.

CNC turning

CNC turning is one of the most used machining methods in CNC machining. During CNC turning, the workpiece makes a rotary motion, and the tool moves in a straight line or a curve. While the tool tip moves relative to the workpiece, a certain workpiece material is removed to form a corresponding workpiece surface.

Applications of CNC Machining

Electronic Products

The full metal casing of 3C products is basically processed by CNC machine tools CNC. CNC has become a must-have for 3C enclosure manufacturers due to its high efficiency, high precision and stable processing quality.

Automobile

CNC machining plays an important role in the automotive industry. It can be said that most automotive parts are processed by CNC machining.

The advantages of CNC machining in automobile manufacturing include multi-axis linkage to obtain the tortuous machining of prototype machining; high precision and good product consistency; high degree of automation, resulting in low labor intensity; CNC also ensures simplicity and high efficiency.

Case: CNC machining car hood model

Material: ABS

Accuracy: 0.01mm

Advantages: high precision, good surface quality, low cost and short time.

Hardware parts processing

Case: CNC machining hardware accessories

Material: hardware parts made of aluminum, copper, stainless steel, etc.

Accuracy: 0.01mm

Advantages: high precision, good surface quality, low cost and short time

Applications: Metal casings, hardware, metal panels, environmental protection equipment parts, non-standard micro-miniature components, copper/aluminum alloy spare parts, medical equipment parts, instrumentation parts, precision machinery parts, communication and communication parts, electronic products High standards and high quality products in the industry of spare parts and auto parts.

Medical Instruments

Case: Aluminum alloy medical robot model production

Size: 30mm*1m

Accuracy: 0.01mm

Advantages: durability and precision

Mold Processing

With the rising labor costs, the preparation of mold templates in the past has been gradually replaced by CNC. Compared with the previous manual preparation, its advantages are: CNC machining holes and hole position relative position accuracy is higher, and work efficiency is extremely Great improvement. In addition, CNC machining processes are required for the machining of curved surfaces, profiled parts, and plastic mold forming cavities in metal molds.

Smart Home

Case: Smart Service Robot

Production materials : ABS, acrylic, sheet metal, PMMA, 45 steel, magnet, aluminum alloy

Size: 1.6m

Accuracy: 0.01mm

Advantages: high precision, fast speed and high processing efficiency

Advantages of CNC Machining

-

High degree of automation and high production efficiency. Except for the manual clamping of the blank, all other processing can be done automatically by the CNC machine.

-

High production efficiency. CNC machine tools can shorten production preparation time and increase the ratio of machining time. Increase productivity by reducing machining time with optimum cutting parameters and optimal path.

-

It has strong adaptability to the processing object. When changing the machining object, Except to changing the tool and solving the blank clamping method, it only needs to be reprogrammed, and no complicated adjustment is required, which shortens the production preparation cycle.

-

High processing precision and stable quality. Machining dimensional accuracy is between 0.005 and 0.01 mm, independent of the complexity of the part. Most of the operations are done automatically by the machine, eliminating human error and increasing the consistency of batch part sizes.

-

A wide range of optional processing materials. The materials processed by CNC are relatively wide, including plastics and hardware.

If you are looking for a reliable CNC machining service to process plastic and metal parts. Please contact our professional team at

[email protected] or contact us by visiting our website, we will provide quotes and suggestions free of charge.

Student Graduation Design Case Study of Expressway Inspection & Emergency Treatment Engineering Vehicles

Student Graduation Design Case Study of Expressway Inspection & Emergency Treatment Engineering Vehicles

+86-18659338188

+86-18659338188  [email protected]

[email protected]

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.

#899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China.